Engineering Services for Industrial Systems

Our engineering services are designed for industrial projects where technical accuracy, reliability, and scalability are critical.

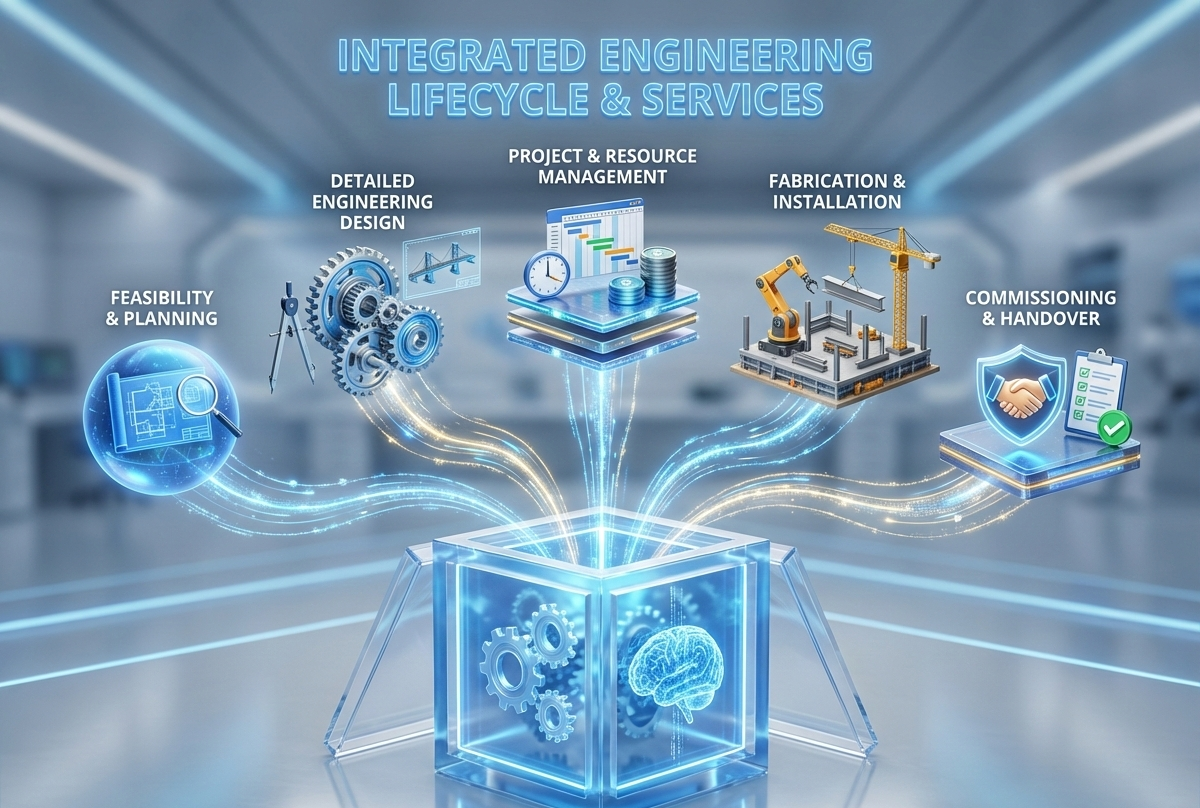

Complete Engineering Lifecycle Services

From initial concept to production-ready documentation, we provide comprehensive engineering support for your industrial projects.

Research & Development

We convert ideas into technically validated concepts ready for detailed engineering.

Core Capabilities

-

Concept Development Transform initial ideas into viable technical concepts with clear specifications and requirements.

-

Feasibility Studies Technical and economic viability analysis including risk assessment and cost estimation.

-

Functional Architecture System-level functional breakdown and interface definition for complex engineering systems.

-

Technology Evaluation Assessment of available technologies and selection recommendations based on performance criteria.

-

Performance Optimization Technical optimization for efficiency, reliability, and cost-effectiveness of engineering solutions.

We provide clear documentation of assumptions, constraints, and recommendations for informed decision-making.

Mechanical Design & Engineering

Detailed engineering design with manufacturing considerations integrated from the start.

Design Capabilities

-

3D CAD Design Professional modeling using industry-standard software like Autodesk Inventor and SolidWorks.

-

Manufacturing-Ready 2D Drawings Complete production drawings with tolerances, surface finishes, and material specifications.

-

Weldment and Sheet-Metal Design Specialized design for fabrication processes with proper bend allowances and weld preparations.

-

Special Purpose Machines (SPM) Custom machinery design for specific manufacturing applications with integration considerations.

-

Reverse Engineering 3D scanning and CAD recreation of existing components with dimensional verification.

-

Assembly Design Complete assembly modeling with interference checking, fastener selection, and assembly sequence planning.

All designs include manufacturability analysis and cost considerations for practical implementation.

Simulation & Design Validation

Validate designs before manufacturing to ensure performance, reliability, and safety.

Validation Services

-

Structural Analysis (FEA) Stress, strain, and deformation analysis under operational loads with safety factor calculations.

-

Thermal Analysis Heat transfer and thermal stress evaluation for components operating in temperature-varying environments.

-

Fatigue Analysis Life prediction under cyclic loading conditions with S-N curve analysis and damage accumulation calculations.

-

Motion & Mechanism Simulation Kinematic and dynamic analysis of moving assemblies with velocity, acceleration, and force calculations.

-

Tolerance Analysis Statistical tolerance stack-up analysis to ensure assembly fits and functional requirements.

-

Design Optimization Iterative improvement based on simulation results to achieve optimal performance-to-weight ratios.

Simulation reduces prototyping costs and prevents field failures through comprehensive virtual testing.

Documentation & Handover

Complete, organized documentation for manufacturing, assembly, and future reference.

Documentation Services

-

BOM and Technical Documentation Complete bill of materials with specifications, supplier information, and procurement details.

-

Manufacturing Drawings Detailed drawings for each component including machining operations, tolerances, and quality requirements.

-

Assembly Drawings Step-by-step assembly instructions with exploded views, fastener lists, and torque specifications.

-

Supplier-Ready Data Packages Complete packages for vendor quotations including all technical requirements and delivery specifications.

-

Maintenance Documentation Manuals and maintenance procedures including lubrication schedules, inspection intervals, and troubleshooting guides.

-

Quality Control Documentation Inspection plans, quality requirements, and acceptance criteria for manufacturing validation.

Documentation follows German engineering standards (DIN) for clarity, precision, and technical accuracy.

Our Engineering Process

A systematic approach ensuring quality, compliance, and alignment with your requirements.

-

Requirement Analysis

Detailed discussion to understand technical requirements, constraints, and project objectives.

-

Concept Development

Generation of multiple concept alternatives with feasibility assessment.

-

Design & Engineering

Detailed 3D modeling, component design, and system integration planning.

-

Simulation & Validation

FEA, motion analysis, and other validation methods to ensure design integrity.

-

Documentation

Complete technical documentation package for manufacturing and assembly.

-

Review & Delivery

Client review sessions and final delivery of all project deliverables.

Ready to Start Your Engineering Project?

Discuss your specific engineering requirements with our technical team. We'll provide a detailed proposal outlining scope, timeline, and deliverables.

Initial technical response within 24 hours

Technical Capabilities & Tools

Industry-standard software and compliance with international engineering standards.

Engineering Software

3D CAD Design:

Simulation & Analysis:

Documentation:

Standards & Compliance

-

DIN Standards

German engineering standards for design and documentation

-

ISO Standards

International standards for quality and engineering practices

-

VDI Guidelines

Association of German Engineers methodology and best practices

-

GD&T (ISO 1101)

Geometric dimensioning and tolerancing for precision design

-

CE Marking Support

Documentation preparation for machinery directive compliance

Representative Projects

Examples of engineering projects demonstrating our technical capabilities and systematic approach.

Pneumatic Gripper Design for CNC Automation Cell

Custom gripper system for automated part handling with rapid cycle times and reliable clamping

Challenge

Handle workpieces Ø40-120mm with single design, <3s cycle time, 6 bar operation

Solution

2-jaw parallel design with adjustable stroke, FEA-validated, optimized topology

Results

2.4s cycle time (20% better), 35% weight reduction, production-ready in 4 weeks

Deliverables:

Manipulator System for 200kg Load Handling

Rail-mounted material handling system with integrated safety features and CE-compliant design

Challenge

Safe handling of 200kg loads, 6m travel, ergonomic manual operation, CE compliance

Solution

Pneumatic balancer with mechanical safety brake, steel construction, fail-safe design

Results

95% operator effort reduction, CE-ready design, 2-day modular installation

Deliverables:

Vision-Guided Robot Integration for Assembly System

Integration design for robotic cell with 3D vision, conveyor synchronization, and sensor networks

Challenge

Integrate 6-axis robot, 3D vision, conveyor sync, multi-sensor network via PROFINET

Solution

Workspace analysis, camera optimization, sensor placement strategy, complete integration design

Results

8s cycle time, ±0.3mm accuracy, 98% uptime, 40% faster commissioning

Deliverables:

Note: These projects represent typical engineering scopes based on our technical capabilities. Specific client details are anonymized to protect confidentiality.

Related Capabilities

Explore our complementary services for complete system solutions.

Automation & Integration

Design of automation systems, robotic cells, and integration solutions aligned with your technology preferences.

Explore Automation ServicesIndustry Applications

See how our engineering services apply to specific industries and applications.

View Industry Applications