Automation System Design & Integration

We design automation systems that are integration-ready, supplier-neutral, and aligned with customer technology preferences.

Supplier-Neutral

No brand bias, only what's best for your project

Customer-Aligned

Works with your preferred technologies

Integration-Ready

Designed for seamless implementation

Automation System Design

Comprehensive design services for industrial automation systems, from concept to implementation-ready engineering.

Assembly Line Concepts

Complete assembly line design including workstation layout, material flow, and process optimization.

Material Handling Layouts

Conveyor systems, AGV/AMR integration, and material transport solutions for efficient logistics.

Robotic Cell Concepts

Robotic workcell design for welding, assembly, machine tending, and material handling applications.

Vision-Guided Automation

Integration of vision systems for inspection, guidance, and quality control in automated processes.

Fixtures & Tooling Design

Custom fixtures, jigs, grippers, and tooling for automated assembly, welding, and processing.

System Integration

Integration of multiple subsystems into a cohesive automation solution with control architecture.

Technology Integration Philosophy

Our engineering designs can be integrated with your preferred technologies — we maintain no brand bias.

Customer-Preferred Technologies

We design around your existing technology investments and preferred suppliers.

Industry-Standard Platforms

Designs compatible with major automation platforms and control systems.

Equivalent Alternatives

Where required, we evaluate and recommend technically equivalent alternatives.

"Component and technology selection is driven by application needs, performance requirements, and customer approval — not brand preferences."

Technology Compatibility

Automation Platforms

Communication Standards

Component Integration

Cost Optimization Approach

Where required, we support cost optimization through careful evaluation of component alternatives, while ensuring:

Technical Compatibility

Equivalent technical specifications and performance

Reliability Assurance

Proven reliability and appropriate service life

Customer Approval

Full transparency and approval before implementation

Supply Chain Stability

Available supply and reasonable lead times

All optimization recommendations include technical justification and risk assessment.

Automation Technology & Integration Standards

Integration Technologies

Industrial Communication:

Vision & Sensing:

Robotics:

Safety Standards

EN ISO 12100: Machinery safety & risk assessment

EN ISO 10218: Robot safety standards

EN ISO 13849: Safety control systems (PLd)

CE Machinery Directive: 2006/42/EC compliance

Safety Devices: Light curtains, safety scanners

Representative Integration Projects

Universal CNC Automation Cell

Robot arm + pallet system + AGV integration for flexible CNC loading

Challenge

Multi-part automation, reduce setup time, AGV coordination

Solution

6-axis robot, pallet changer, AGV dock, safety integration

Results

20% setup reduction, flexible handling, safe collaboration

Deliverables:

Vision-Guided Assembly Cell

3D vision system integrated with robot for random-oriented part handling

Challenge

Random part orientation, ±0.3mm accuracy, PROFINET integration

Solution

Camera optimization, lighting design, sensor network, communication

Results

8s cycle, ±0.3mm achieved, 98% uptime, fast commissioning

Deliverables:

Projects represent typical automation integration scopes. Client details anonymized. All designs are supplier-neutral.

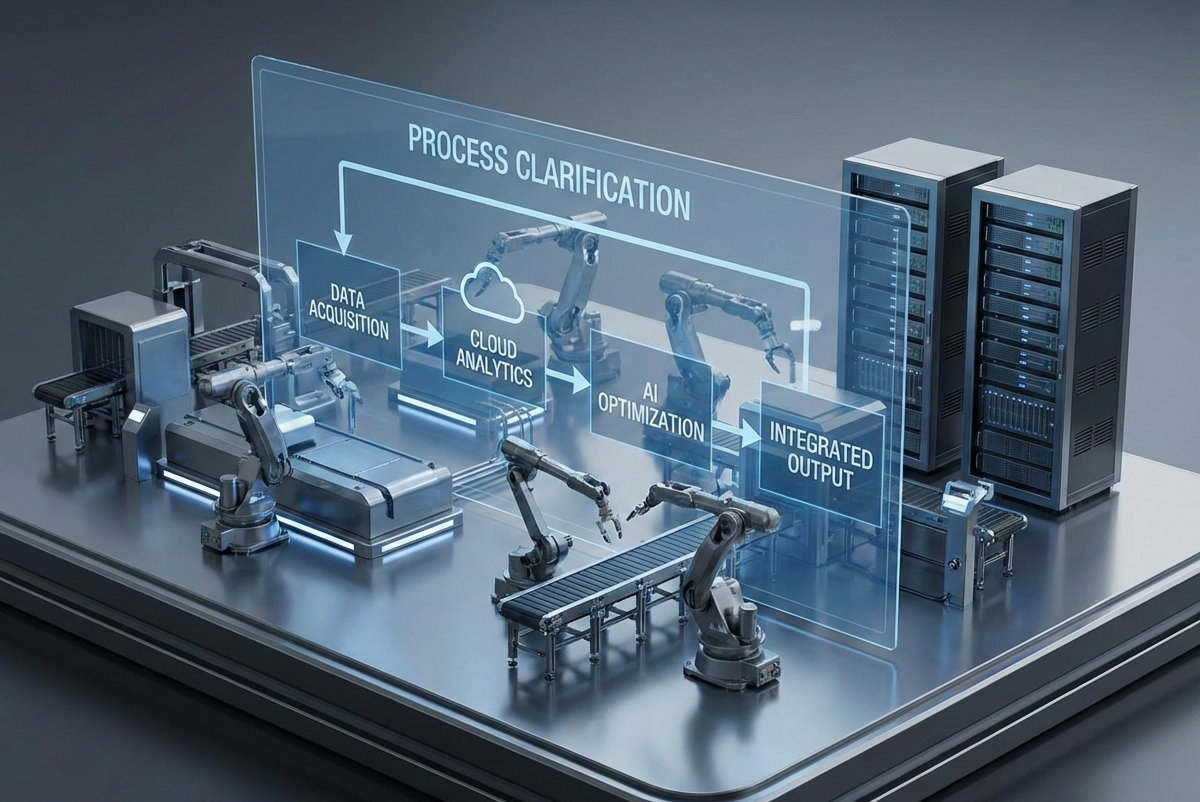

System Integration Process

Requirements Analysis

Comprehensive analysis of technical requirements, production goals, and integration constraints.

Concept Development

Creation of system architecture, workflow diagrams, and preliminary design concepts.

Detailed Design

Complete engineering documentation including 3D models, schematics, and specifications.

Interface Definition

Specification of all mechanical, electrical, and software interfaces between components.

Documentation & Handover

Complete documentation package including integration manuals, wiring diagrams, and acceptance criteria.

Each phase includes client review and approval before proceeding to the next.

Typical Applications

Special Purpose Machines

Custom machines for specific manufacturing processes, testing, or assembly operations.

Automated Assembly Systems

Complete assembly lines with robotic workstations, vision inspection, and quality control.

Vision-Guided Handling

Robotic systems with vision guidance for part identification, orientation, and placement.

Production Tooling & Fixtures

Custom tooling, fixtures, and end-effectors for automated manufacturing processes.

Start Your Automation Project

Discuss your automation requirements with our engineering team. We'll provide integration-ready designs that work with your preferred technologies.

Technical discussion scheduled within 48 hours